NBR HNBR sila aila sila aila sila sila no ka ha'alulu

Hōʻike huahana

| Nā hiʻohiʻona | |

| Materail | Laa hoailona:NBR,HNBR,ACM,EPDM,VMQ,PTFE,SBR,FKM,PU |

| Puna:SWP,SUS | |

| Metala pahu: Carbon steel | |

| kalakala | ʻEleʻele, ʻulaʻula, melemele, uliuli, ʻalani, ʻeleʻele, poni, etc |

| Loaʻa | OEM, ODM |

| ʻAno | Serrated, Grooved, Corrugated, flat, apo, nā mea ʻē aʻe e like me ke koi o ka mea kūʻai aku |

| Palapala hōʻoia | ISO9001, TS16949, SGS |

| Palapala noi | Hoʻokuʻu kaʻa, ʻenekini kaʻa, ʻōnaehana hydraulic, ʻōnaehana kaomi ea, etc. |

Hāʻawi ʻo Max Auto Parts Ltd i nā sila aila ʻaila kūloko, hiki iā mākou ke kūʻai mai NOK, NAK brand no nā mea kūʻai aku.

kikoʻī

| mea | waiwai |

| Palapala hōʻoia | 1 MAKAHIKI |

| Kahi i kumu | Kina |

| Zhejiang | |

| Kapa inoa | Max |

| ʻO ka mānoanoa | 6.4-6.9 g/cm3 ma hope o ka mahu ʻana |

| Mea waiwai | Fe-C-Cu Pauda |

| Nā mea lapaʻau i luna | ʻO ka hoʻoheheʻe ʻana i ka mahu, 2 mau hola, Fe3O4: 0.004-0.005mm, degere o ka hoʻokahe 2-4% |

| lawelawe | OEM ODM |

| ʻO ka mānoanoa | 6.4-6.9 g/cm3 ma hope o ka mahu ʻana |

| ʻAno | LU, Milling, Huli |

| Helu kumu hoʻohālike: | Hana hana maʻamau |

| Inoa mea kūʻai: | Pauda Metal Sintered Part for Shock Absorber |

| Kaʻina hana | Sintering+ Cnc |

| Palapala noi | Hoʻopaʻa haʻalulu |

| ʻAʻole i hōʻike ʻia | ISO 2768 - m / H14, h14, +- IT14/2 |

| ʻO kā mākou pono | 1. ʻOi aku ma mua o 3000 mau molds i kēia manawa, mālama i kāu kumukūʻai mold 2. ISO/TS 16949:2009 palapala 3.Competitive kumukūʻai 4.Strictly quality control capacity of APQP,FEMA,MSA,PPAP,SPC |

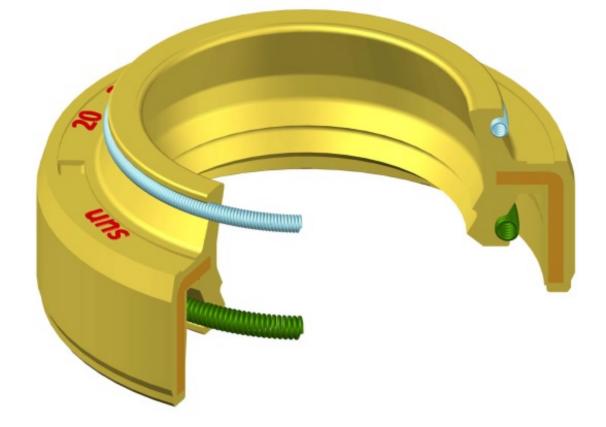

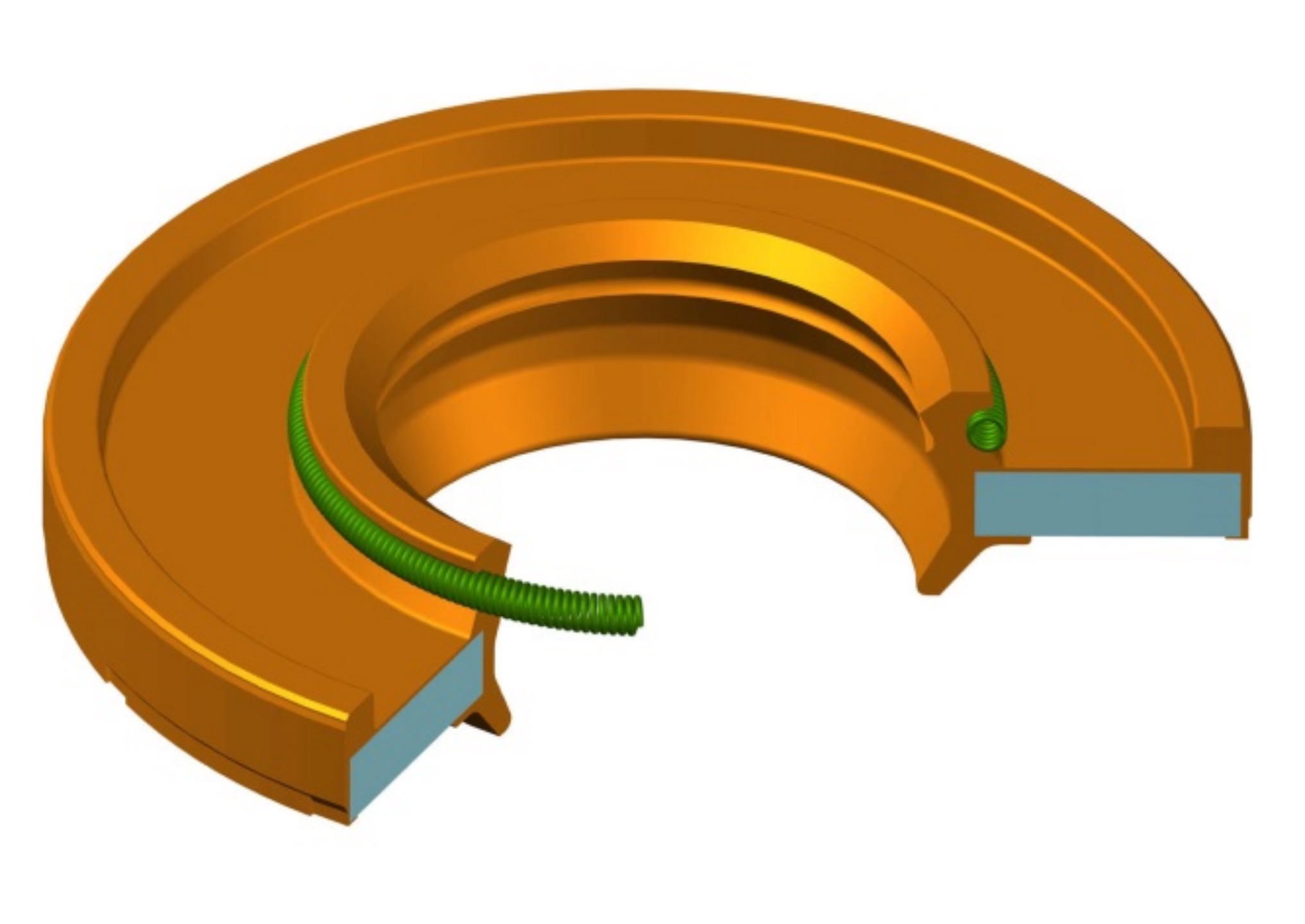

ʻO ka hoʻolālā sila ʻaila

Hoʻokaʻawale ʻia nā sila ʻaila i hoʻokahi ʻano a me ke ʻano hui.

ʻO ke ʻano hui ʻia ke kiʻi a me nā mea lehelehe hiki ke hoʻohui manuahi ʻia, hoʻohana maʻamau no nā sila aila kūikawā.

Aila sila a me ka noi

3.1.1 Sila aila

ʻO ka silaʻaila ka sila o kaʻaila lubricating.ʻO kāna hana ka hoʻokaʻawale ʻana i ke keʻena aila mai ka honua o waho, hoʻopaʻa i ka aila i loko a pale i ka lepo ma waho.Hoʻohana nui ʻia nā sila aila no ka hoʻopaʻa ʻana i ka lawe kaʻa a me nā bearings hub.

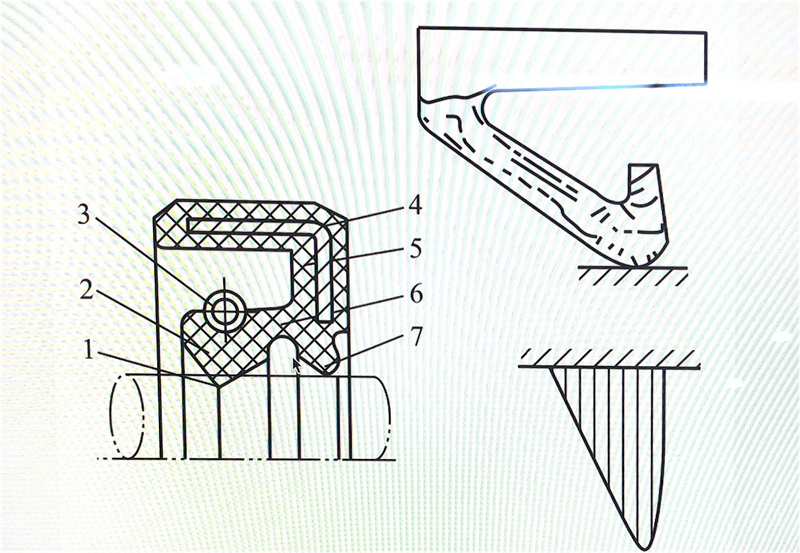

(1) ʻO nā hiʻohiʻona a me nā ʻenehana loea o ka sila ʻaila

ʻO ka ʻokoʻa ma waena o ka sila aila a me nā sila lehelehe ʻē aʻe he lehelehe me ka ʻoi aku ka ikaika, ʻo ka laula o ka ʻili hoʻopili sealing he haiki loa (e pili ana i 0.5mm), a ua kuhikuhi ʻia ke kumu hoʻohele o ke koʻikoʻi pili.Hōʻike ke kiʻi i ke ʻano maʻamau o ka sila aila a me ke kiʻi schematic o ke koʻikoʻi pili o ka lehelehe.ʻO ke ʻano kea o ka sila ʻaila a me ka pūnāwai hoʻopaʻa i ʻoi aku ka maikaʻi o ka uku ʻana i ka lehelehe no ke kumu.No laila, hiki i ka silaʻaila ke loaʻa ka hopena hoʻopaʻa maikaʻi me ka ikaika radial lehelehe liʻiliʻi.

Fig. ʻO ke ʻano maʻamau o ka sila ʻaila a me ke kiʻikuhi schematic o ke koʻikoʻi pili lehelehe

1-lehelehe;2-leialii;3-punawai: 4-iwi;5-lalo: 6-pūhaka;7-lehelehe mea kōkua

Ke hoʻohālikelike ʻia me nā mea hoʻopaʻa hoʻopaʻa inoa ʻē aʻe, loaʻa i ka sila ʻaila nā mea maikaʻi.

①Maʻalahi a maʻalahi ka hana.Hiki ke hoʻoheheʻe ʻia nā sila aila maʻalahi i ka manawa hoʻokahi, a ʻo nā sila ʻaila paʻakikī loa he hana paʻakikī ʻole.Hiki ke hoʻopili ʻia ka sila ʻaila metala me ka metala a me ka lāʻau e hana ai i ka sila aila i koi ʻia ma o ke kahakaha ʻana, gluing, inlaying, molding a me nā hana ʻē aʻe.

②Māmā a me nā mea hoʻohana liʻiliʻi.ʻO kēlā me kēia sila aila ka hui pū ʻana o nā ʻāpana metala lahilahi a me nā ʻāpana ʻōpala, a he liʻiliʻi loa kona hoʻohana ʻana, no laila he māmā loa ke kaumaha o kēlā me kēia sila aila.

③ He liʻiliʻi ke kūlana hoʻokomo o ka sila aila, liʻiliʻi ke ʻano axial, maʻalahi ke hana, a paʻa ke ʻano o ka mīkini.

④ Hana maikaʻi ke sila a me ke ola lawelawe lōʻihi.Loaʻa iā ia kekahi adaptability i ka vibration o ka mīkini a me ka eccentricity o ke kumu nui.

⑤Easy wehe a mālama.

⑥Maikaʻi ke kumukūʻai.

ʻO ka hemahema o ka sila aila ʻaʻole hiki ke kū i ke kaomi kiʻekiʻe, no laila hiki ke hoʻohana wale ʻia e like me ke sila no ka lawe ʻana i ka ʻaila lubricating.

ʻO ka pae hana o ka sila aila: ʻo ke kaomi hana ma kahi o 0.3MPa;ʻo ka wikiwiki laina o ka ili hoʻopaʻa ʻana ma lalo o 4m / s, a ʻo ke ʻano wikiwiki he 4 ~ 15m / s;ʻo ka mahana hana -60 ~ 150 ° C (e pili ana i ke ʻano o ka ʻōpala);pili ʻO ka mea waena ka aila, ka wai a me ka wai corrosive nāwaliwali;ʻO ke ola lawelawe he 500 ~ 2000h.

(2)Kaʻaila sila sila

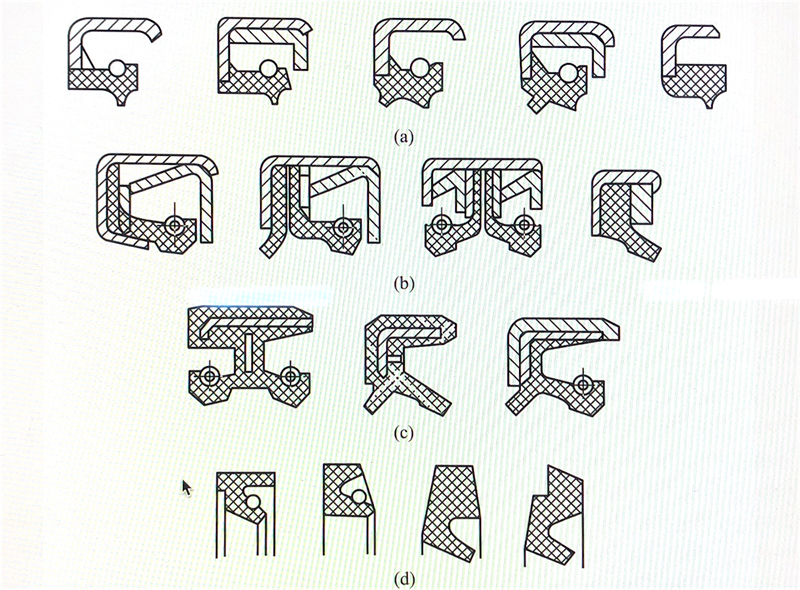

Hōʻike ʻia ke ʻano o ka sila ʻaila maʻamau i ke kiʻi

Kii |ʻO ke ʻano o nā sila ʻaila maʻamau

① Hoʻopili paʻa ʻO ka hiʻohiʻona o kēia ʻano he hiki ke hana ʻia a hana ʻia ka ʻāpana metala a hana ʻokoʻa, a laila hoʻopaʻa pū ʻia me ke kāpili e hana i kahi ʻano iwi i hōʻike ʻia, nona nā mea maikaʻi o ka hana maʻalahi a me ke kumu kūʻai haʻahaʻa.ʻO nā ʻāina e like me ʻAmelika Hui Pū ʻIa a me Iapana ka hapa nui o kēia ʻano hana.Hōʻike ʻia ko lākou mau ʻāpana keʻa ma ke Kiʻi (a).

②Assembly structure ʻO ia ka hoʻohui ʻana i ka lehelehe lāʻau, ka pahu metala a me ke apo puna e hana ai i ka sila ʻaila.Pono ka iwi o loko a me waho, a hoʻopaʻa i ka lehelehe.He mea maʻamau ka pahū e pale ai i ka puka ʻana mai o ka puna [Figure (b)].

③Ka ʻiʻini i uhi ʻia i ka lāʻau.Hoʻopili ʻo ia i ka iwi metala i kuʻi ʻia i ka lāʻau e hana i kahi ʻano iwi i loko.ʻOi aku ka paʻakikī o kāna kaʻina hana, akā maikaʻi kona rigidity a maʻalahi hoʻi e ʻākoakoa, a ʻaʻohe ona koi kiʻekiʻe no nā mea pā kila [Figure (c)].

④ Sila ʻaila ʻaila piha piha ʻO kēia ʻano sila ʻaila ʻaʻohe iwi, ʻaʻohe pūnāwai kekahi, a ua hoʻoheheʻe ʻia ke ʻano holoʻokoʻa e ka lāʻau.Hōʻike ʻia e ka ʻoʻoleʻa maikaʻi ʻole a hiki ke hoʻololi i ka plastic deformation.Akā hiki ke hoʻohana ʻia me nā ʻokiʻoki, ʻo ia wale nō ke ʻano no nā ʻāpana ʻaʻole hiki ke hoʻokomo ʻia mai ka hopena o ke kumu akā pono e hoʻopaʻa ʻia me ka ʻaila [Fig.(d)].

(3) Na sila aila no na kaa

Ua kapa ʻia nā sila lehelehe rotary shaft he sila aila.E like me ka hoʻolālā, ua māhele ʻia nā sila aila i loko o nā sila aila o loko, e like me ke ʻano B (me ka ʻole o ka lehelehe kōkua) a me ke ʻano FB (me nā lehelehe kōkua) nā sila aila;ʻO nā sila aila iwi i hōʻike ʻia, me ke ʻano W (me ka lehelehe kōkua ʻole) a me ke ʻano FB (me ka lehelehe kōkua);hui ʻAno sila ʻaila, me ke ʻano B (me ka lehelehe kōkua ʻole) a me ke ʻano FZ (me ka lehelehe kōkua).ʻO ke ʻano o ka sila ʻaila he mana nui i kāna hana.I nā makahiki 1970 a me 1980, ma o ka noiʻi hohonu e pili ana i ke ʻano o ka sila aila (ʻano ʻāpana a me ka nui), kahi ʻano o nā mea ʻike e pili ana i ka hoʻolālā ʻana (e like me ka oil seal radial force, lip contact width, friction torsion, lehelehe wela) ua kūkulu ʻia.lita a me ke ola ho'āʻo mea hana aiʻole bench), e kau ana i ke kumu no ka manao o ka aila hana sila .The manao loina o ka aila sila structural parameters (ke ano a me ka nui o ka pūhaka, e like me ka nui o ka lehelehe a me ka puna groove, interference nui, shape a me ka nui o lehelehe kōkua, a me nā mea ʻē aʻe) o ka sila ʻaila i hoʻoholo maoli ʻia.Ua hoʻohana ʻia kēia mau loina i nā kūlana hoʻolālā aila ʻaila GB 987711, GB 987712 a me GB 987713.

Ke hoʻohālikelike ʻia me ka sila ʻaila i loko, ʻoi aku ka kiʻekiʻe o ka coaxiality hoʻonohonoho ʻana o ka ʻaila ʻaila i hōʻike ʻia, akā ʻoi aku ka paʻakikī o ka hoʻokele ʻana i ka ʻenehana hana a me ka pololei ʻana o ka mold a me ka wili huahana.ʻO nā sila aila kaʻa ʻē aʻe ke hōʻike maoli ʻia nā sila aila iwi, ʻoiai ʻo nā sila aila kaʻa kūloko ka nui o nā sila aila iwi o loko.I ka makahiki 1980 mua, ua hoʻonohonoho ka Ministry of Chemical Industry i kahi noiʻi nui e pili ana i ka hoʻomohala ʻana i nā sila aila iwi i hōʻike ʻia, me ke ʻano a me ke ʻano o ka hoʻohālikelike ʻana o ka sila aila iwi i hōʻike ʻia, ka hoʻopaʻa ʻana o ka ʻōpala a me ka iwi, ka antirust. ʻO ka mālama ʻana i ka iwi i hōʻike ʻia, ka puna a me ka hoʻolālā ʻana a me ka Processing, ka ʻenehana wili huahana, a me nā mea ʻē aʻe i aʻo ʻia, akā ma muli o nā kumu like ʻole, ʻaʻole i hoʻokō koʻu ʻāina i ka hana nui o nā sila aila iwi i hōʻike ʻia.